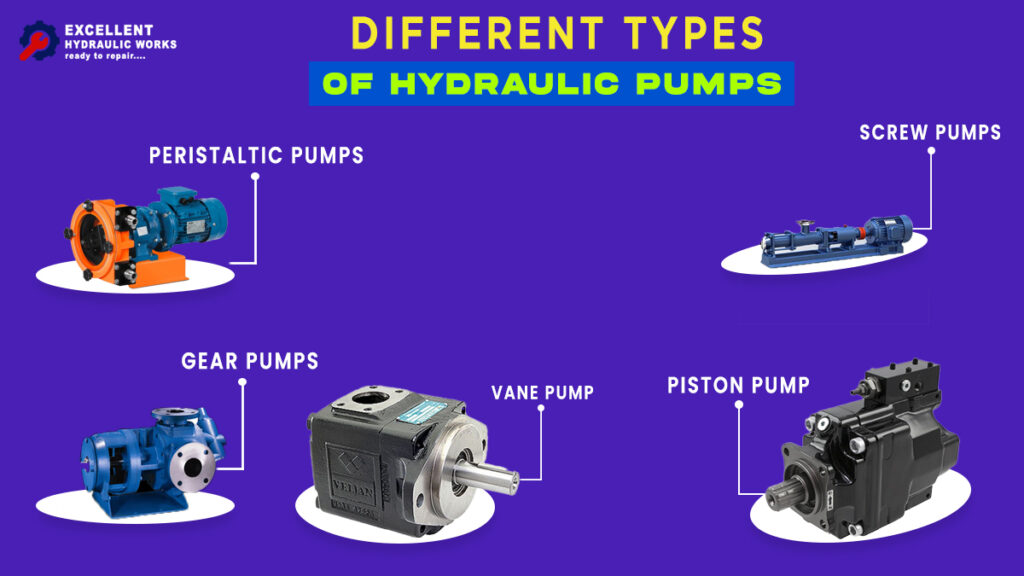

Heart of every hydraulic system that live inside the machine is not even cared when it runs perfectly fine. Hydraulic Pumps get noticed when they stop working and bring an entire factory floor to a screeching halt. If you do work with heavy equipment, manufacturing machinery, or anything that moves with hydraulic power, knowing your pumps is not just helpful—it become essential. It is a machine that converts mechanical energy into hydraulic energy by moving fluid. If the pump breaks? Nothing works. There are different parts used in a hydraulic system of machinery. In this article, you will know about types of hydraulic pumps and how they work.

1. Gear Pumps

Best for: Simple systems, low-to-medium pressure work

Used in: Tractors, loaders, plastic machines, Forklifts, Lube System and old machinery

These are the most common and with fewer moving parts. Gear pumps use two meshing gears to move fluid and get the job done- external and internal.

How It Works:

Two identical gears (usually spur gears) sit side by side. As they rotate in opposite directions, they trap fluid in the space between the gear teeth and the casing. Fluid is carried around the outside of the gears (not between them) and pushed out through the outlet as the gears continue to turn. It has high-pressured capability and used for fixed displacement applications in reversible environment as well.

Pros: Low maintenance, budget-friendly, compact

Cons: Can’t handle super high pressure, kind of noisy, not good with contaminated fluids

2. Vane Pumps

Best for: Medium-pressure systems, smoother operations

Used in: Injection molding machines, mobile equipment, presses, power steering

Vane pumps use a rotating disc with sliding vanes that move fluid in same amount of flow even as the pressure changes. These are quiet pumps and good for when you want performance but without the drama and that’s way hold an important place in Industrial hydraulic Systems.

If we talk about its design, it has a rotor inside a circular chamber which has slots inside with vanes. These flat, sliding pieces are spring loaded and pushed outward by centrifugal force as rotor spins.

How It Works:

As the rotor turns, the vanes slide out and meet the chamber wall resulting in formation of sealed pockets between themselves, the rotor, and the housing. On the inlet side, the space between vanes expands and create a vacuum. This sucks hydraulic fluid into the chamber, kind of like the machine is breathing in. As the rotor keeps turning, these pockets of fluid are carried around the chamber. They’re sealed off by the vanes, so the fluid can’t escape—like being trapped in a very polite elevator. On the outlet side, the chamber narrows, squeezing the pockets. This compresses the fluid and forces it out under pressure.

Pros: Quieter than gear pumps, smooth flow, consistent output, self-adjusting vanes

Cons: Does not love dirty oil, not made for extreme pressure

3. Piston Pumps

Best for: High-pressure tasks and precise systems

Used in: Excavators, aerospace tech, heavy machinery that could flatten your car

These are the overachievers of the hydraulic world. Piston pumps are displacement device which move liquid and gases using pistons. These are precise, powerful to deal with solid particles, high viscous fluid and can operate under high pressure settings for various displacement options.

How It Works:

The piston retracts and create a vacuum inside the cylinder. Hydraulic fluid rushes in through the inlet valve, like it’s just been invited to a party with free snacks. The piston moves forward, squeezing the fluid and forcing it out through the outlet valve under high pressure.

Pros: High efficiency, high pressure, very accurate

Cons: Expensive, more moving parts = more maintenance

There are two types of Piston pumps:

Axial Piston Pump- Cylinders arranged in a circular pattern and move parallel to the shaft. These have fixed and variable displacement and work with attached swashplate or wobble plate.

Radial Piston Pump– Pistons arranged like spokes of wheel points towards central shaft. When shaft rotates, it forces pistons in and out. It is heavy-duty and works in ultra-high-pressure system.

Piston pumps are mostly used in Heavy machinery such as Excavators, marine and offshore hydraulic systems, cranes, and construction equipment.

4. Screw Pumps

Best used for: Smooth, continuous flow in low-to-medium pressure setups

Industrial uses: Lubrication systems, oil burners, elevators, things that shouldn’t jerk or stutter

Work with two or three interlocking screws to push fluid gently and steadily. If your system needs calm, uninterrupted flow, a screw pump is your best bet.

How It Works:

Fluid enters one end of the pump and gets trapped between the screw threads and the pump housing and as the screws rotate, these pumps carry the fluid forward in a smooth, continuous motion—kind of like a spiral conveyor belt made of metal. The intermeshing screws create a sealed cavity, so the fluid doesn’t slip backward. The pressure builds up, and the fluid is discharged smoothly.

Pros: Very quiet, very reliable

Cons: Can’t handle high pressure, not the fastest

5. Peristaltic Pumps

Best for: Delicate fluids displacement

Used across Industries: Medical and food industries

These pumps work on principle of squeezing fluid through a flexible tube using rollers. Very rare to use across heavy-duty hydraulic systems but worth a mention because they can handle fluids that would destroy other pumps.

Pros: Great for sensitive or corrosive fluids

Cons: Low pressure, niche use only

So, here is a recap of Hydraulic Pump Variety and its Uses:

| Task | Suggested Pump |

| Budget-friendly, basic systems | Gear Pump |

| Smooth, quieter performance | Vane Pump |

| High-pressure, precision jobs | Piston Pump |

| Constant and Quiet Flow Operation | Screw Pump |

| Special FLuid | Peristaltic Pump |

Final Thoughts

Hydraulic pumps aren’t just “one size fits all.” Choosing the right type can make or break your entire system—literally. If you’re not sure what your machine needs, talk to someone who lives and breathes hydraulic oil (hint: us).

Got a pump that’s leaking, whining, or refusing to do its job? We fix those too.

Need Help Diagnosing or Repairing Your Hydraulic Pump?

We do not sell pumps. We just bring them back from the dead.

If yours is leaking, rattling, overheating, or simply refusing to work, don’t wait until it’s a total failure.

- Call us or fill the enquiry form for a quick inspection or advice.

- On-site support available at your location in Delhi NCR